Reply: how can the supply chain improve flexibility under the epidemic?

Source / logistics information (id:wuliuzhiwen)

Author / Ye Shuai

With more and more uncertain factors, the value of supply chain is being paid more and more attention.

This is not only reflected in the continuous mention of "maintaining the stability of the supply chain industry chain" at the national level, but also reflected in the increasingly urgent needs of enterprises in building an agile, flexible and stable supply chain.

The latter is reflected in the upgrading of sealing control, but also in the great promotion. Combing a series of actions of relevant enterprises before 618, we can find that platforms and businesses pay more attention to the certainty of supply chain performance, and enterprises with corresponding supply chain service capabilities are also more vocal.

Through a series of war reports after 618, we can also find that brands are making rapid progress in Omni channel layout. Whether it is e-commerce platforms such as tmall and jd.com, or emerging channels such as Tiktok Kwai and jd.com home, the same brand can often be seen in a considerable number of war reports.

Not only that, while online channels are in full swing, brands and dealers are still working on offline channels, including seeking new increments by expanding the sinking market.

Baishi supply chain should be deeply touched by the above changes. This is not only because in 618 this year, it has given solutions such as intelligent warehouse distribution, but also because it has cooperated with a number of industry leading enterprises in recent years, witnessing the channel transformation and sales growth of a number of brands.

01

Three capabilities support the full link solution

Offline + online, multiple channels, blooming everywhere - the omni channel layout of brands naturally brings great challenges to the logistics supply chain.

Taking the daily chemical industry as an example, it has long supply chain, difficult to predict demand and high inventory costs. The diversification of channels has produced a series of new pain points. For example, due to the difficulty of inventory sharing and classification, the lack of unified management, resulting in repeated stocking, high inventory and rising costs; Online and offline channels coexist, but the implementation ability in terms of shop, supplement, adjustment and return is weak, and the response efficiency to demand is low, which is also not conducive to expanding emerging markets.

How to break the game? For the daily chemical industry, Baishi has provided a full link solution: Based on the full scenario logistics SaaS system and the perfect warehouse distribution network, create a one-stop Omni channel sales and logistics supply chain collaborative solution for the daily chemical industry, quickly respond to the peak logistics full link demand, and provide efficient, standard and flexible supply chain services from order to bill.

Data shows that the program includes three capabilities:

Digital intelligence system service: a 100% self-developed logistics system cluster supported by big data, Internet of things and AI technology solves problems such as quality inspection and warehousing, warehousing management, picking and delivery and express optimization, transportation management, connecting with customer systems to get through data, ensuring the positive and negative integration of production, distribution, replenishment and after-sales, and realizing fast and accurate full link response.

Intelligent warehousing operation: while applying large-scale automatic equipment to carry out standard and efficient warehouse operations, it has more than 15 times of flexible production capacity, calmly cope with the peak of big promotion, and provide a more smooth logistics guarantee.

Omni channel network distribution: Based on logistics product resources, form a national network route with 100% coverage; Provide one-stop s2b2c services from factories, warehouses, businesses and stores to improve the efficiency of warehouse allocation and save management costs.

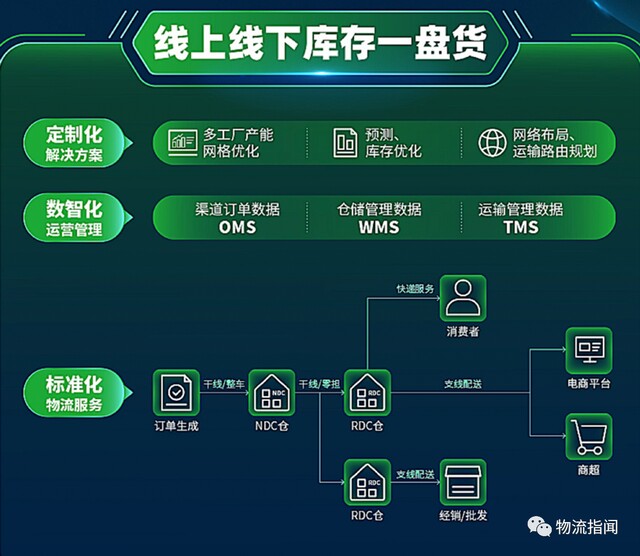

Based on the above three capabilities, Baishi helps enterprises realize one inventory of online and offline inventory. As shown in the following figure:

In terms of effectiveness, according to the data provided by Baishi, for the daily chemical industry, its one inventory solution has achieved an omni channel order fulfillment rate of 96%, an inventory accuracy rate, a timely delivery rate, and a timely receipt rate of 99.9%, and a timely receipt rate of 90%. More importantly, through the graded sharing of national warehouse inventory, supplemented by the corresponding transportation resources, the inventory originally scattered in the general warehouse, regions and dealers at all levels has realized unified scheduling and optimization, helping enterprises reduce inventory costs and reduce capital pressure; In addition, the unified management of Omni channel orders, coupled with the visualization and digitization capabilities, also provides support for decision-making, achieving more accurate sales forecasts and more timely logistics delivery.

02

How does the logistics supply chain become the "third profit source" of enterprises?

For brands, the opportunities brought by Omni channel are obvious, but it is also a complex change. For example, channel integration needs to solve the problems of membership system, commodity information, order management, etc., and the biggest difficulties and challenges come from inventory management, operation efficiency and quality. The latter is also the embodiment of the competitiveness of supply chain service providers.

Wei Yongqiang, vice president of Baishi group and deputy general manager of Baishi supply chain, holds a similar view. In an earlier interview, Wei Yongqiang said that cost and quality are the main factors that affect brands' choice of supply chain service solutions. Among them, supply chain service cost is related to two dimensions: supply chain cost and operation cost.

In order to reduce operating costs, relevant enterprises generally adopt the application of advanced equipment and tools, and arrange the planned workload based on reasonable estimates, so as to reduce the idle and waiting time of personnel. The latter obviously tests the operation climate more - if the planned quantity is not estimated accurately, the personnel and equipment arrangement will produce deviation, insufficient will not guarantee the service quality, and excessive will cause cost waste.

To this end, Baishi supply chain, on the one hand, through in-depth communication and evaluation with customers, studies customers' commodity sales methods, promotion cycles, and scientifically arranges plans. On the other hand, it improves operation efficiency through advanced tools, refined management, and competitive incentive system. "Combined with the physical attributes of goods and sales relevance, the warehouse should be reasonably arranged, and then the plan and prediction should be well done, the process and operation links should be well planned, and the matching staff distribution system, the cost will be reduced," Wei Yongqiang said.

The above ideas of Baishi have been verified in the cooperation with customers in the daily chemical industry. Take laundry detergent as an example. In B2C business, its customer unit price is low and the package weight is high, resulting in a high proportion of logistics costs in the whole customer unit price. This also brings challenges to the control and optimization of warehouse allocation costs. Guoyangyang, senior project manager of Baishi supply chain Guangdong Branch, said that in recent years, Baishi supply chain has been improving efficiency by constantly changing the operation logic and mode in the library. In terms of packaging, on the premise of ensuring quality, optimize the cost of single average consumables; In terms of distribution, on the premise of win-win with suppliers, strive for relatively reasonable costs and optimize the whole chain.

Equally important is the optimization of supply chain costs brought about by Baishi supply chain. According to Zhang Wang, director of Baishi supply chain solutions, from the perspective of production, the factories of fast-selling brands are distributed in different parts of the country, and the categories produced by different factories are different. This means that the warehouse network layout needs to be reasonably distributed, so as to realize the optimization of the supply chain. This also puts forward a new topic for tripartite Logistics: we should not only stand in the perspective of implementation, but also design the warehouse network layout from the perspective of the optimization of Party A's entire supply chain.

This is also the change being brought about by Baishi supply chain. After cooperating with Baishi supply chain, the brand not only has a denser warehouse network, but also has a deeper and more refined warehouse network, thereby improving the delivery timeliness and turnover efficiency.

Of course, the above achievements not only rely on the overall optimization of warehouse network, but also need the support of warehouse operations. To this end, Baishi supply chain has also been emphasizing fine management. "We will split each operation link and related actions, and study the configuration standards and rationality of these actions."

The measures of refined management have achieved both cost reduction and quality improvement. In addition, digital capability also provides guarantee for service quality, for example, "baishiyoupai".

"Youpai can be understood as the express delivery supplier in the preferred demand area", guoyangyang said, "All express companies are in the scope of optional suppliers. Baishi supply chain e-commerce warehouse uses many express companies to ship a large number of packages every day, and has accumulated a large amount of data. We evaluate the strength of local express sites in combination with the express timeliness, delivery quality and other data in the system. Based on this, Baishi youpai system can realize intelligent optimization of delivery orders. We will eventually choose 2-3 express suppliers to support each other and learn from each other, Finally realize the optimization of distribution resources and quality. "

In this way, in terms of express resources, Baishi not only has greater and more flexible choice space, but also has an additional guarantee in the face of uncertain situations such as the epidemic. Of course, in terms of overall planning, it also puts forward new tests. In addition to relying on the system for scientific and intelligent order splitting, Baishi has also taken a series of measures in management, such as monitoring the operation quality of express delivery through operation quality management personnel, dealing with exceptions, and KPI assessment of suppliers; In daily operation, work with suppliers to manage standardized operations.

03

From one inventory to production supply and marketing balance

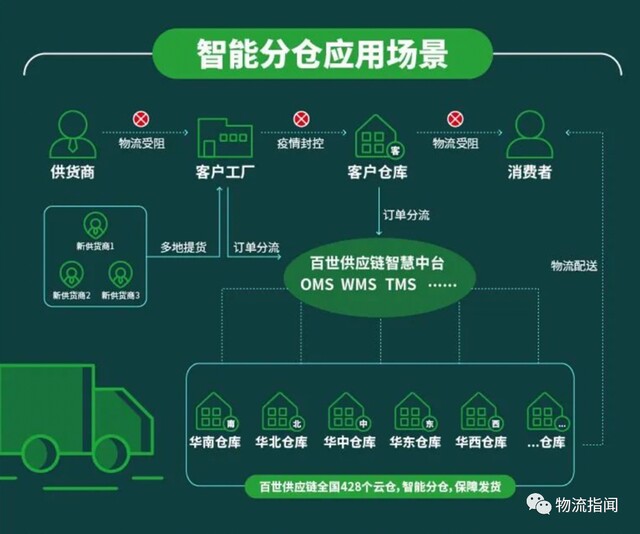

As mentioned above, the promotion and the temporary changes brought about by the epidemic have made the certainty of supply chain performance the focus of attention of platforms and businesses. In this regard, a number of enterprises with supply chain service capabilities have given solutions. Taking Baishi supply chain as an example, it can help customers build new sub warehouses in other regions of the country, and it can complete site and equipment construction, team and system docking and other actions in only 2 days at the fastest; After the completion of warehouse distribution, customers can continue to implement the original delivery plan and divert orders to areas not affected by the epidemic through the Baishi supply chain system.

Both the warehouse splitting scheme and the aforementioned inventory solution depend on the accumulation of Baishi supply chain in three aspects:

1. National warehouse network

In the era of digital supply chain, cloud warehouse is not only infrastructure, but also the middle stage in the whole supply chain service chain. According to the data, by the end of March this year, Baishi supply chain had 416 self operated and franchised cloud warehouses, with a total management area of 3.04 million square meters. Moreover, other resources in Baishi ecosystem, such as Baishi express, Baishi international and Baishi cloud, have also laid the foundation for Baishi's supply chain to output systematic solutions.

2. Industry experience

Unlike the standardized services of express delivery, supply chain services are more customized. Different industries need different solutions. Even in the same industry, different sub categories are different. Baishi has accumulated in the field of supply chain for a long time: the supply chain business unit is the second business unit established by Baishi group after the cloud business unit. Over the years, it has been deeply involved in many industries such as shoes and clothing, fast sales, etc., and has provided intelligent supply chain services to more than 3000 brand enterprises.

3. Digital capability

A survey of "challenges facing the supply chain" shows that the interviewed enterprises think that the challenges of the digital transformation of the supply chain, the low end-to-end visualization of the supply chain, and the inaccurate prediction rank in the top three. Earlier, some relevant people pointed out that as the world enters the vuca era, enterprises need to improve their adaptability and predictability. How to meet the above needs? The answer is digitalization.

Digitalization is the strength of Baishi. Its self-developed full process supply chain logistics system has the ability of big data analysis, and can provide functions such as intelligent prediction, intelligent goods preparation, intelligent inventory, intelligent order splitting, intelligent scheduling, etc. according to customer needs. With the full link digital intelligence system, Baishi supply chain has also established an intelligent operation monitoring system for brand customers to monitor the progress of orders in real time throughout the whole process, early warning abnormal orders, and ensure the stability of performance service quality.

Thanks to the above, Baishi has brought a series of assistance to its customers: a solid warehouse network and open system ensure the reliability of performance; Sufficient capillaries ensure the logistics performance of customers' sinking market; The comprehensive storage, distribution and related value-added services of the whole supply chain meet the needs of the brand and KA customers; Based on the collection, analysis and corresponding suggestions of the real data of the whole link, enterprises can also make better decisions.

What is more noteworthy is that the segmented network originally operated by dealers is also expected to gradually become an integrated and collaborative digital network through the digitalization of channels and logistics service network, so as to help enterprises realize the coordination and balance of production, supply and marketing.

"We hope to be a digital supply chain logistics solution provider in the future". According to Zhang Wang, the director of Baishi supply chain solutions, Baishi supply chain now has many aspects of competitiveness, such as digital genes, perfect solutions, solid operation capabilities, and the corporate culture of customer first.

Source / logistics information (id:wuliuzhiwen)

Author / Ye Shuai