Dry goods: the starting point for the intelligent transformation and upgrading of traditional factory logistics

Source / Shanghai Tianrui logistics consulting (id:tianrui_logiwis)

For existing factories, systematic diagnosis and review are needed to clarify their existing problems, opportunities, constraints, etc., and choose suitable entry points for logistics transformation and optimization. The following content selects successful experiences and cases in the process of transformation and upgrading of manufacturing enterprises to elaborate and share.

01

Basic mode of transformation and upgrading

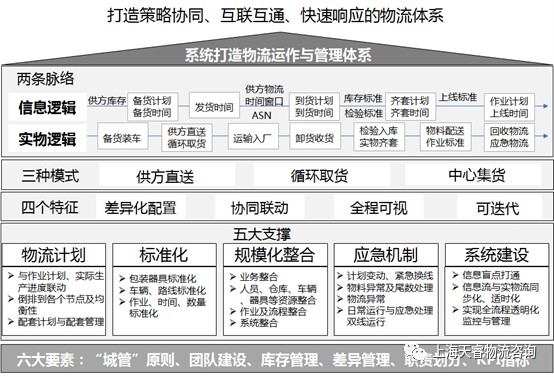

Logistics is the core element in the transformation and upgrading of factories. Its basic mode and content are shown in Figure 8-6:

Figure 8-6 logistics transformation and optimization model of existing factories

(1) Supply chain, logistics strategy and value orientation

It is necessary to determine the supply chain, logistics strategy and value orientation of the enterprise, so as to form a relative focus on the development direction and reach a common understanding of the enterprise. For the operation of the factory, delivery, cost, quality, service, speed, efficiency and other factors need to be taken into account, and these factors affect, restrict and promote each other. Therefore, enterprises should combine the industry environment and their own characteristics, and choose the key elements to improve their competitiveness as the focus. For example, an enterprise faces a market environment in which product homogenization is serious, product gross profit is not high, and enterprises in the industry are deeply affected by high inventory. After analysis, the enterprise takes the response speed and delivery level of supply chain and logistics as an important starting point, forming a 3-5-year supply chain and logistics development strategy, Its internal logic is: through rapid response, it can not only improve the level of delivery service, improve customer satisfaction, but also continuously reduce the inventory of the whole channel, so as to ensure that the cost and gross profit are at a better level in the industry, and gradually form an industry-leading competitiveness. In addition, the development direction of digitalization and intellectualization of the factory also needs to be clearly defined in the strategy and the medium and long-term vision, so as to reach the consensus and common practice of all departments.

(2) Establish an integrated planning and collaborative management system

Establish a planning integrated collaborative management system to realize the collaborative linkage between production and marketing plans, production plans, procurement plans, logistics plans and shipping plans. The ultimate embodiment of planning ability is to quickly identify and respond to market fluctuations. Therefore, the planning system should break the "drum beating and flower passing" series mechanism and establish an interconnection mechanism with supply chain planning as the core. When a condition changes, the system can quickly identify risks and differences, and guide other plans to make reasonable judgments and adjustments.

(3) Entry point for planning and improvement

Find the right entry point for planning and improvement, and take this as the starting point for the end-to-end transformation and optimization of logistics. Whether it is inbound logistics, in plant logistics or finished product logistics, we should always grasp the attributes of its value chain in the process of logistics transformation. Every point in the logistics chain is a link between the preceding and the following, which affects the whole body. Therefore, we must have overall and systematic thinking. At this stage, we also need to continue to pay attention to the improvement and progress of organization, process, packaging, informatization and visualization, facilities, teams and talents, emergency logistics, etc.

(4) Seek breakthroughs

On the basis of certain achievements in the first, second and third steps, seek breakthroughs in automation, digitization and intellectualization, focusing on the gradual application and upgrading of intelligent unit design, automatic logistics facility application, artificial intelligence facility application, man-machine and object digitization, logistics scene digitization, logistics plan intellectualization, logistics information platform construction, etc.

02

Basic principles of transformation and upgrading

In the process of logistics transformation and upgrading, existing enterprises need to pay attention to the following principles:

(1) Principle of differentiation

Formulate differentiated logistics strategies for different products, materials, production lines, suppliers, customers, etc., and formulate solutions that match their characteristics. For example, strictly control the inventory of materials with relatively stable supply and quality from close suppliers, and adopt the strategy of on-time arrival, while for materials with relatively short supply from long-distance suppliers, small volume, you can appropriately reserve more inventory and adopt the strategy of batch arrival; MTS (production by inventory) mode is adopted for products with strong versatility and stable sales, while MTO (production by order) mode is adopted for products with personalized and large demand fluctuations. Therefore, the logic and mechanism of demand guidance and collaboration with their corresponding customers also need differentiated settings.

(2) Standardization principle

Reduce the complexity of logistics as much as possible through the standardization of products, packaging, processes, appliances, data and business. For example, when there is no standardization of material packaging, the location of material labels, the setting of data collection points, the specifications of logistics facilities, warehouse location planning, etc. cannot be unified, and the entire logistics system will be extremely complex, and it will be very difficult to achieve automation and intelligence.

(3) Operation simplification principle

In the process of sorting out the logistics operation process, the ECRs rule is adopted to simplify the operation and process as much as possible, that is, cancel, merge, rearrange and simplify. For example, reduce unnecessary sub packaging of materials through packaging standardization; Reduce unnecessary stock in and stock out through stock out operations; Replace manual counting with automatic counting; Reduce the number of points, the difficulty of handover or cancel handover through material unitization; Reduce logistics breakpoints and inventory by establishing continuous flow.

(4) Principle of collaborative interconnection

Realize the coordination of plans, data, operations, etc. among business departments, between enterprises and suppliers, and between enterprises and customers. Specifically, in the process of logistics planning, we should define its communication mode, communication rules and collaboration mechanism through the process, and realize "online" collaboration through the docking of information systems. For example, in the production planning process, the linkage between customer demand (order), supplier production and pre process production should be considered; It is necessary to consider the sharing and effective interpretation of key information such as plans, orders, inventories and demands among all departments of the enterprise, as well as between the enterprise and customers and suppliers.

(5) Process control principle

Logistics is a dynamic process composed of multiple nodes. Logistics management emphasizes the dynamic management of plans, standards, implementation, differences, etc. in the logistics process. Therefore, it is necessary to emphasize the whole process visualization and risk early warning of the logistics process. For example, we should not only be able to present the inventory data on each node in real time, but also be able to dynamically monitor the rationality of inventory in combination with inventory standards; It should not only reflect the route and location of delivery vehicles in real time, but also predict the shortage risk in combination with the logistics plan; It can realize real-time analysis and presentation of logistics process indicators such as personnel efficiency, equipment utilization, equipment failure rate, logistics plan achievement rate, and material completion rate.

03

Formulate logistics strategy

The enterprise needs to formulate a detailed strategic landing plan, and the subsequent system construction process can be carried out based on the logistics strategy. See 3.4.2 logistics strategy of conceptual design for specific strategy formulation. Here, only the main contents and manifestations of the logistics strategy of a manufacturing enterprise are shown.

The manufacturing enterprise is a leading enterprise in the industry, and its overall operation ability, supply chain operation ability and production and operation ability are benchmarks in the industry. The transformation and improvement of logistics is one of the measures that the enterprise has always adhered to. After continuous optimization for more than ten years, the internal logistics foundation, logistics layout, streamlining, distribution, automation, punctuality and logistics informatization of the manufacturing plant of the enterprise have a high level. In this context, the enterprise needs to seek higher breakthroughs in supply chain and logistics, and has formulated a new logistics "Five-Year Plan", as shown in Figure 8-7.

Figure 8-7 logistics strategic planning of an enterprise

First of all, the factory has conducted a comprehensive logistics review and diagnosis. Combined with the investigation and analysis of customer needs, it believes that the bottleneck of its logistics is mainly reflected in the inbound logistics link. There is still a big gap between factories and suppliers in logistics standardization, logistics plan coordination, logistics resource utilization, logistics emergency mechanism, logistics informatization, logistics process monitoring, etc. "there is no factory gate for management", resulting in low support of incoming logistics for production stabilization. Therefore, a new logistics development strategy has been formulated, which takes inbound logistics as the starting point, establishes a new logistics operation and management system, and creates a logistics system with strategic coordination, interconnection and rapid response. Compared with the current situation of factory logistics, there should be at least three breakthroughs:

1. Go out of the factory and carry out deeper and broader collaboration with suppliers, including the guidance of suppliers' production, logistics and other capabilities;

2. Guided by efficient delivery, its main value line is to better respond to customer needs through the improvement of supply side capacity;

3. Write interconnection into the strategy and implement it in the construction of interconnection process and information network.

Secondly, the factory defines the development strategy of "two veins, three modes and four characteristics". The two threads refer to the two logical chains of information flow and real logistics, which should not only realize their own connection, but also realize the synchronization of information flow and real logistics, so as to lead the logistics planning, process optimization and system upgrading of the plant; The three modes are the inbound logistics mode combining direct delivery from the supplier, circular picking up and central collection, focusing on the continuous integration of flow, vehicles, personnel, warehouses, facilities and other resources in the inbound logistics link; The four characteristics refer to the basic principles that need to be grasped at all times in the transformation process, adopt differentiated strategies for different suppliers and materials, strive to realize the collaborative linkage with various departments and suppliers through logistics planning, emphasize the whole process monitoring and visualization of the logistics process, emphasize real-time management and rapid response, and always locate in the future digital and intelligent iterative route in the planning and transformation process, Clarify the implementation path of "one-time planning and step-by-step implementation".

Third, the factory defines five capacity supports, which can be understood as strategic measures. To realize the strategy, we must go to the place where we must adhere to it for a long time and focus on investment. The main idea is to focus on the construction of five capabilities: logistics planning, standardization, large-scale integration, emergency mechanism and system construction, which are the capabilities that must be established in the whole process of logistics transformation. These capabilities can support the realization of strategies and strategies.

Fourth, clarify the key orientation of logistics planning and operation in the strategy:

1. Realize the balance of logistics through production equalization and supply intensification, and finally realize the stability and economy of production. Before the systematic planning, the production plan and procurement plan did not consider the logistics needs. There are often large fluctuations in the logistics of various periods, suppliers, lines, workshops and lines. Fluctuations are the main reasons for uneven busy and idle times and efficiency losses, because logistics capacity needs more resource matching and capacity allocation to meet the maximum demand in order to ensure that it meets the demand, However, as a result, the utilization rate of various resources is only about 50%. Therefore, in the process of planning, we need to consider the balance of the system, such as the matching relationship between products and production lines and workshops should be relatively fixed, the types and quantities of suppliers and supplied materials should be relatively fixed, and the logistics lines and workshops should have a certain matching relationship. Of course, everything is a relatively better logical plan made by comprehensive analysis on the premise of demand pull, and the fluctuations caused by the actual demand changes need to be supplemented by unimpeded information mechanism, flexible plan changes, rapid response mechanism, etc.

2. Improve the utilization of logistics resources through systematic logistics planning. Before planning, the supplier invested a large number of drivers, car following personnel, plant stationed personnel, etc. to serve the factory. These personnel are scattered in all links and can hardly be effectively controlled, resulting in huge safety hazards and waste. At the same time, the utilization rate of these personnel is very low. For example, a supplier stationed five service personnel in the factory. When the supplier arrived, these personnel had jobs, but when they did not arrive, These people will be idle; For example, car attendants follow vehicles to and fro between suppliers and enterprises every day and wait for unloading. In fact, these times have no value. It is not just the personnel of the supplier, including the personnel in the factory, unloading sites, warehouses, appliances, loading and unloading facilities, delivery vehicles outside the factory, etc. due to the lack of integration planning, their utilization can not be guaranteed, resulting in high comprehensive operating costs of the factory. Whether these costs are borne by the supplier or the enterprise itself, they will be reflected in the purchase price of raw materials and the cost of products. By establishing a third-party logistics organization (which can be a real third-party logistics company or other forms of companies, such as establishing a logistics company in cooperation with suppliers), we can obtain great integration benefits by unified planning, operation and management of the logistics business of many suppliers and factories.

04

Consolidate the logistics foundation

The logistics intellectualization of existing factories is a relatively long-term goal and a guide for continuous improvement. For most existing manufacturing plants, the top priority is to take logistics as the main line, realize the collaborative operation of upstream and downstream supply chain, and realize the coordination of inbound logistics, in plant logistics and finished product logistics, so as to improve the operation efficiency of the plant. Here, what needs to be discussed in the logistics transformation of the factory is not the subject of digitalization and intellectualization, but the process of straightening out the logistics management logic and consolidating the logistics foundation, which is a "necessary course" on the road to intellectualization for existing factories.

When the factory is in the vortex of frequent shortage, what needs to be solved is to establish an effective linkage between logistics plan and production plan, promote refined inbound logistics management, and ensure the stability of production; When the factory capacity cannot meet the market demand, what is needed is to improve the response ability and speed of logistics, establish a just in time material supply mechanism, and save more area for expanding production; When the factory inventory is piled up, what is needed is to establish a reasonable and effective inventory strategy to guide the inventory control at a reasonable level; When the factory's finished product inventory remains high and is frequently out of stock, what is needed is to straighten out customer needs and order management, and establish a collaborative mechanism with production and logistics to achieve effective order priority management; When the inventory of self-made parts in the factory is high and takes up a large amount of production area, what is needed is to connect the internal value flow, realize the physical or planned connection, and reduce the internal logistics breakpoints.

On the other hand, many basic problems faced by existing factories have nothing to do with digitalization and intelligence. When the factory always has inconsistency between accounts and materials, which leads to management confusion, what is needed is to constantly improve the bill of materials and improve the consistency and synchronization of Physical Logistics and information flow; When various kinds of material packaging and inaccurate quantity in the factory lead to various problems and waste, such as material receiving, internal handover, counting, frequent switching packaging, production line site chaos, it is necessary to establish standardized, unitized and generalized material packaging standards; When the factory is faced with the management that the logistics site of each link is chaotic, inefficient and cannot be effectively monitored, what is needed is to establish the logistics operation standards and processes of each link, so that the logistics operation "has laws to abide by and illegal can be found".

05

Eliminate logistics breakpoints

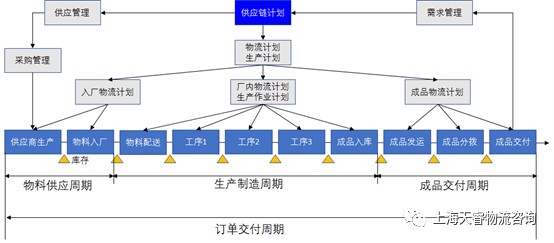

The focus of logistics planning is to create continuous flow and create the basic conditions for rapid flow. As shown in Figure 8-8, taking logistics as the main line and looking at value flow from an end-to-end perspective, its essence is to provide a higher level of delivery services at a reasonable and low cost. In such a complex system, overall balance is more important than local efficiency, and global collaboration is more important than node execution. The optimization of value flow with logistics as the main line should be driven by plan coordination to realize the reasonable planning of time and inventory. Its purpose is to accurately respond to demand, shorten delivery time and reduce inventory. Therefore, it is necessary to plan the logistics process as a whole to achieve end-to-end "de facto balance".

Figure 8-8 value flow chart with logistics as the main line

The reason for the de facto balance is that enterprises cannot "tangle" with the ideal balance or theoretical balance. The end-to-end process of logistics is like a continuous flow production line. For a real production line, ie engineers will record the action time in detail with a stopwatch, accurately define the action to shorten the processing cycle, and set the ideal production line balance rate through the method of station balance, so that the actual output of each line can reach 90% or even higher of the theoretical output in theory. However, the actual operation situation is not so ideal, because there will always be various interference situations in the actual operation process, there will be varying degrees of movement variation in each station, and there will also be differences in workers' technical proficiency and speed, resulting in many efforts made by engineers to balance production may be futile. In fact, if variation and interference cannot be eliminated, the more balanced the production line is, the worse its output performance may be.

For a production line with a balance rate close to the ideal balance, if the effective output of each station is 90%, the output of the whole production line will be 90% to the power of n (n is the number of stations of the production line). Therefore, more important than the station balance of race against the clock is to reserve a buffer of working hours on the basis of appropriate station balance (for example, reserve about 20% protective capacity for some stations that are often disturbed) Set up inventory as a buffer and manage (reduce) interference and variation to maximize the overall output of the production line (rather than the output of each post). For the "production line" of logistics, in order to maximize the effective output of the whole "production line", it is necessary to optimize the overall efficiency through plan coordination, route planning, buffer deployment and other measures:

(1) Planned collaboration

First, supply and demand can be effectively balanced through supply chain planning; Secondly, through the overall planning of the plan, the reasonable setting of time and inventory buffers in the whole logistics chain is formed; Third, establish the linkage response between logistics plan and production plan. Planning is the engine of supply chain and logistics, and effective planning management is the basic premise of realizing value chain optimization.

(2) Logistics mode and route planning

For inbound logistics, it refers to the planning of arrival mode and inbound logistics route; For in plant logistics links, it refers to the continuous flow planning of internal logistics moving line and production, so as to minimize the breakpoints of production and logistics; For the finished product logistics link, it refers to the planning of logistics network and logistics lines.

(3) Buffered deployment

In order to deal with various abnormalities in the logistics process, it is necessary to set up a buffer of inventory and time in necessary places. For example, the injection molding workshop of the factory cannot realize physical direct connection (continuous flow) with the general assembly line due to the number of equipment, change time, economic batch, output beat and other reasons, so it is necessary to set the necessary inventory between the injection molding workshop and the general assembly workshop as a buffer, and the size of this inventory depends on the necessary buffer time. If the reasonable buffer time is 1 day, Then the inventory in this buffer zone needs to meet the production plan demand of the next day. For the whole logistics chain, inventory is a bridge that effectively connects the upper and lower nodes. Not all nodes should have inventory, nor can all nodes have no inventory. If there is inventory on node a, there may be no inventory on node B. how to deploy, we need to carry out unified deployment through system planning, and set the inventory standard on the necessary nodes.

06

Develop professional ability

Establish logistics management organization and develop professional ability. Logistics is an end-to-end thinking, and production is a "precision strike" thinking. Therefore, production personnel generally cannot manage logistics well. In the factory, they should have a separate logistics management organization and define professional logistics management positions. In particular, they should pay attention to logistics planning, logistics process, inventory management, logistics standardization, and talent training and post construction in logistics automation, digitization, and intelligence. For the construction of logistics management organization, please refer to Chapter 6 (6.2 logistics management organization of intelligent factory).

07

Application of logistics technology and facilities

Logistics automation, digitalization, and intelligent solutions and technologies have wider universality and maturity. To improve the automation and intelligence of production system, it is necessary to carry out non-standard design in combination with the specific manufacturing process of products, especially in the face of personalized products of users. Almost every kind of products and even every specific product process are different, and the production equipment of various industries and enterprises can be different, which cannot be widely used and promoted. Therefore, it is difficult to invest in automation, and it is necessary to customize non-standard automation Expensive smart devices. However, although the logistics system has complex scenarios, it needs to meet the following requirements, such as large and small pieces, whole in and out, whole in and out, sorting out and direct distribution posts, materials and product units of various sizes and specifications. After the standardized design of material packaging and the standardized design of logistics operation process, the key equipment, core components, and The control system and logistics related information system will have strong versatility. Even the design of non-standard system is only the difference of appearance size, and its core action is still "conveying, turning, entering and leaving, picking, grabbing, stacking, positioning, reading", etc. because of this, relevant technologies and facilities are becoming more and more mature in the continuous application process, which creates excellent conditions for the realization of logistics intelligence in the factory.

On the other hand, the existing factories do not need to invest all at one time to promote the intelligent transformation of logistics, but can follow the steps of "one-time planning and step-by-step implementation". Horizontally, it can be piloted first and then copied to minimize investment risks. For example, a product line can be piloted first, and then copied and promoted to other product lines or other workshops after successful operation and summarizing experience; Automatic stereoscopic library, conveyor line, RGV, AGV system, etc. are also based on module structure, which has strong scalability and iteration. They can be invested in batches, and can also realize the compatibility of technologies in different stages. Vertically, it can be carried out successively or synchronously from one link to several links. For example, layout planning can be implemented first, and then automation transformation can be implemented; First do a good job in the internal transformation of the factory, and then promote it to the transformation of suppliers; First improve internal logistics, then improve inbound logistics and finished product logistics. As long as the logic of logistics system planning is correct, we can fully adjust the pace in combination with the actual situation of the enterprise and the pilot situation, and control the risk at a low level.

In the process of Logistics Intelligent Planning and transformation of existing factories, we should always grasp the value orientation of "planning is for better operation", apply the logistics automation import analysis model and other related tools in Chapter 3, and select the necessary nodes for transformation pilot and promotion. It is not necessary to do it in one step.

The construction of logistics automation, digitalization and intelligence is the key to realize the value leap of the factory. When the factory has a clear logistics logic and a good logistics management foundation, the factory can gradually promote the construction of logistics automation and digitalization. Logistics facilities generally have good versatility and flexibility. Transportation, handling, loading and unloading, storage, picking, distribution, station docking, etc. have relatively mature technical applications. In the process of implementing logistics automation, we need to pay attention to the following points:

(1) Select the appropriate transformation point through the logistics automation analysis model. For the existing factory, not all nodes are suitable for automatic transformation, or some nodes do not have investment value;

(2) The selection of appropriate logistics technologies and facilities through analysis requires specific analysis in combination with material characteristics, flow, environment, etc. for example, different levels of logistics automation facilities such as mechanization, semi automation, automation, intelligence, etc. may be used in continuous or discrete transportation, independent storage or dense storage, pallet storage or bin storage Make scientific choices in modes and technologies such as automatic picking or semi-automatic auxiliary picking;

(3) As far as possible, choose the vertical automatic connection, select local areas, such as a factory, a workshop or a production line, and carry out systematic automatic planning and pilot for the whole process of material unloading - material receiving - material inspection - material warehousing - material storage - material picking - material distribution - material online - empty container recycling. Of course, the overall planning is still emphasized before the pilot to ensure that expansion and iteration can be carried out on the basis of the pilot;

(4) Abandon the traditional concept that automation is "machine replacement". The core value of logistics automation lies in the end-to-end connection to achieve rapid flow, reduce the storage, waiting and breakpoints in the process of material circulation, shorten the circulation time, and reduce the physical inventory in the whole process.

08

Logistics Digitalization

Digitalization of logistics is an inevitable process of intelligent transformation of logistics, which needs to be based on Digitalization of logistics. The basic performance of logistics digitalization is that all logistics processes are "online", paperless, automatic data collection and transmission, automatic data analysis, automatic risk and anomaly warning, visualization, etc. In essence, logistics digitalization is the process of solidifying the logic, experience and knowledge of factory logistics management into the information system. The premise of logistics digitalization is "online elements". Through the application of RFID or barcode, the digitalization of materials and related equipment and personnel, such as inductive material labels, equipment labels, document labels and personnel labels, is realized, so that people, machines and materials all have the conditions of dynamic data automatic collection and two-way communication. The basis of logistics digitalization includes digitalization of materials, locations, routes, facilities, personnel, etc.:

(1) Digitalization of materials: Digitalization of materials is generally realized by digitalization of packaging containers. Each material needs to specify a unique container and quantity in each link. By pasting barcode on the material container or embedding RFID, the material information can be written and collected. When selecting and designing material packaging containers, it is necessary to combine code reading technology and collection methods, clearly define the location of material labels and carry out standardized settings, so as to ensure that data can be read efficiently in the process of material circulation.

(2) Digitalization of warehouse location: the warehouse location here refers to the generalized warehouse location, that is, the storage point and pause point in the process of material flow, such as the parking space of the unloading yard, the unloading buffer location, the inspection waiting area, the warehouse area and storage location, the sub loading area, the picking area, the line storage location, etc. these physical locations need to be able to be defined in the information system, and the virtual identification in the information system using spatial positioning technology, such as UWB (ultra wideband) technology. In addition, each area and warehouse location shall be identified to facilitate identification and positioning in the process of logistics operation. The digitalization of logistics path is formed by establishing physical and virtual connections between various regions.

(3) Digitalization of facilities and personnel: intelligent logistics system is actually the interconnection and interaction of people, machines and things, and it needs to realize two-way communication between them. Therefore, facilities and personnel must also be "online" to form the continuity of management and minimize offline workflow. For example, mechanized equipment such as forklifts and tractors need RFID cards to identify their identities, so as to facilitate the scheduling and management of the equipment. The equipment should be equipped with a displayable terminal to display its specific tasks and instructions. The equipment should also be equipped with a reading device to realize the information interaction with materials and inventories, so as to realize the digital collaboration between people, machines, objects and locations; Personnel also need to have fixed ID cards and identity definitions, and receive and send instructions through handheld terminals or mobile terminals; Since facilities and personnel are equipped with inductive tags, their routes, times, etc. can be analyzed and more accurate arrangements and scheduling can be carried out.

(4) Digitalization Foundation: in addition to having a good digitalization foundation, logistics digitalization should be gradually realized from three aspects: data acquisition, data application and data Intelligence: data acquisition is to establish the data acquisition ability of the whole process of logistics, and realize the automatic collection of dynamic data through scanning equipment, induction equipment, photo identification equipment, etc; Data application is to establish the structure and logic of data management, establish a data model in combination with the focus of logistics management and control, solidify experience and knowledge into the system and application through the model, and realize automatic analysis, early warning and decision support; Data intelligence needs to build a logistics control tower, establish a logistics management platform, and realize the autonomy of logistics planning, scheduling, adjustment, coordination, and difference management on the basis of logistics big data, and gradually move towards intelligence.

Source / Shanghai Tianrui logistics consulting (id:tianrui_logiwis)